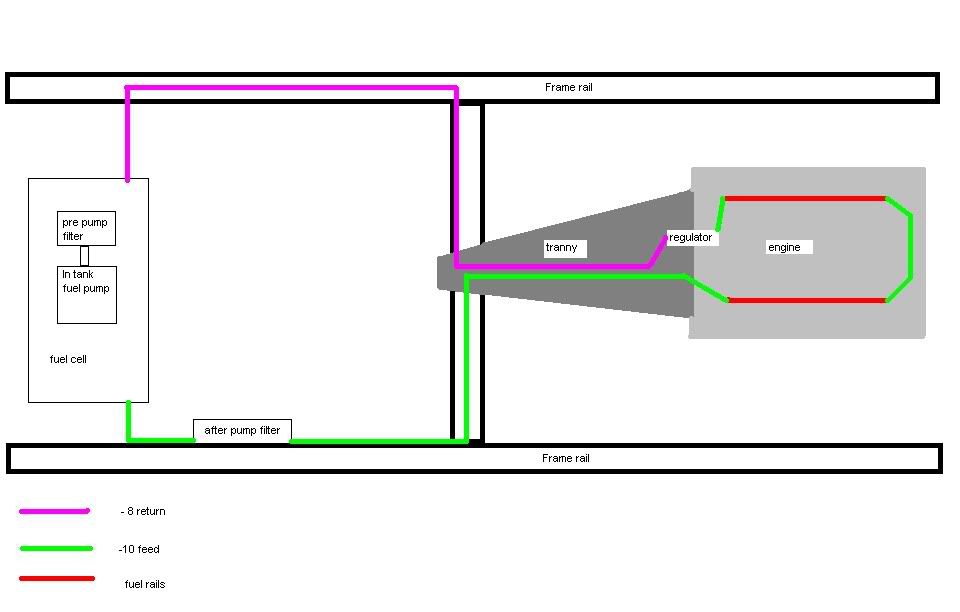

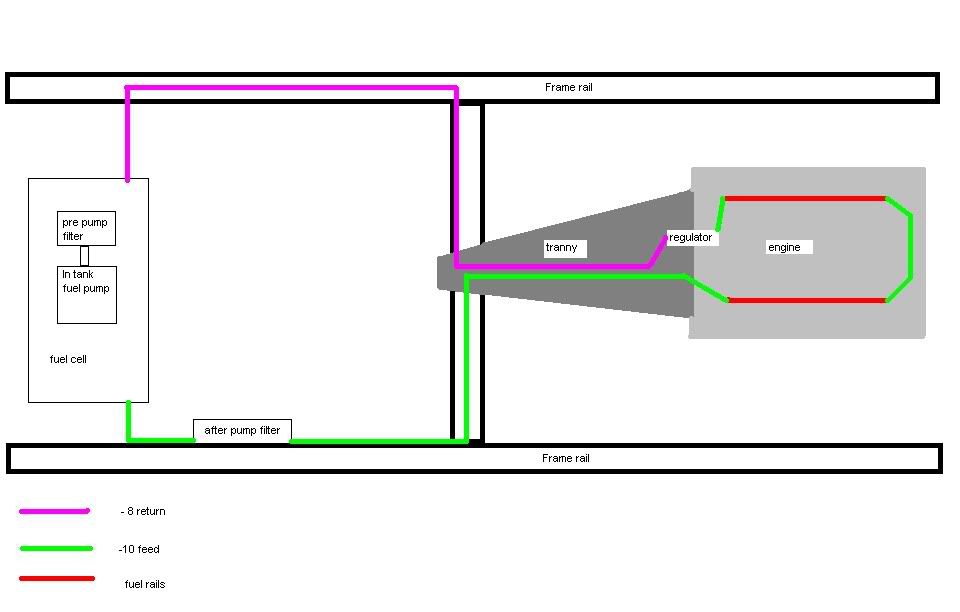

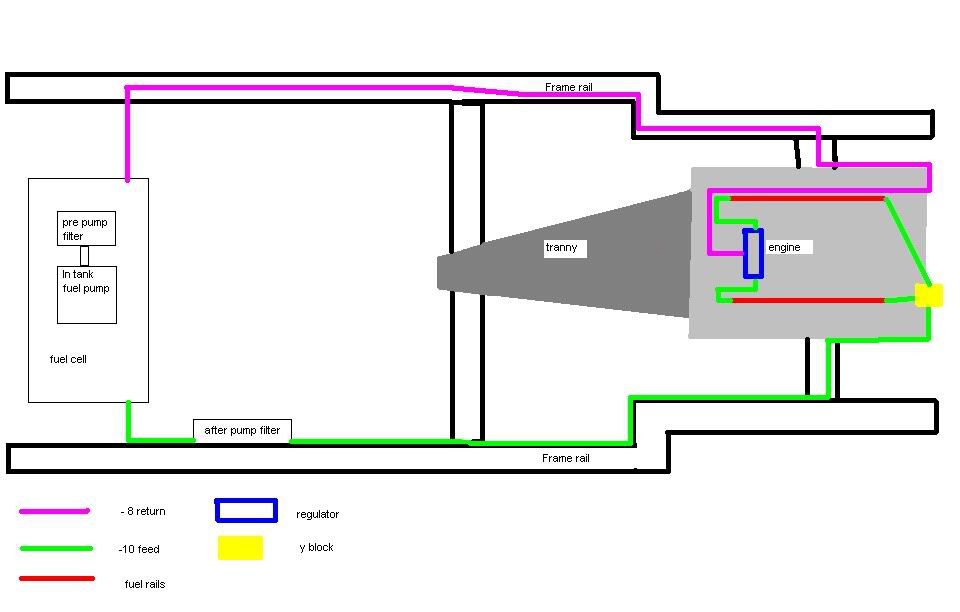

Okay so this will be on a turbo 351w setup, I want to have the fuel line and return come in and exit at the back of the motor, and just a cross over line on the front. But im trying to keep it as clean looking as possible, so I dont really want my lines coming from the frame rail under the hood. I was thinking of bringing them to the middle of the car across the tranny X member, then mounting them to the tranny tunnel with some cushion clamps and running them up to the back of the engine over top the tranny. Here is a pic of what im talking about. Do you all see any problem with this as long as it is kept away from moving and hot parts? Will it pass tech inspection at a track?

Or do you all have any ideas of your own to keep it nice and tidy under the hood?

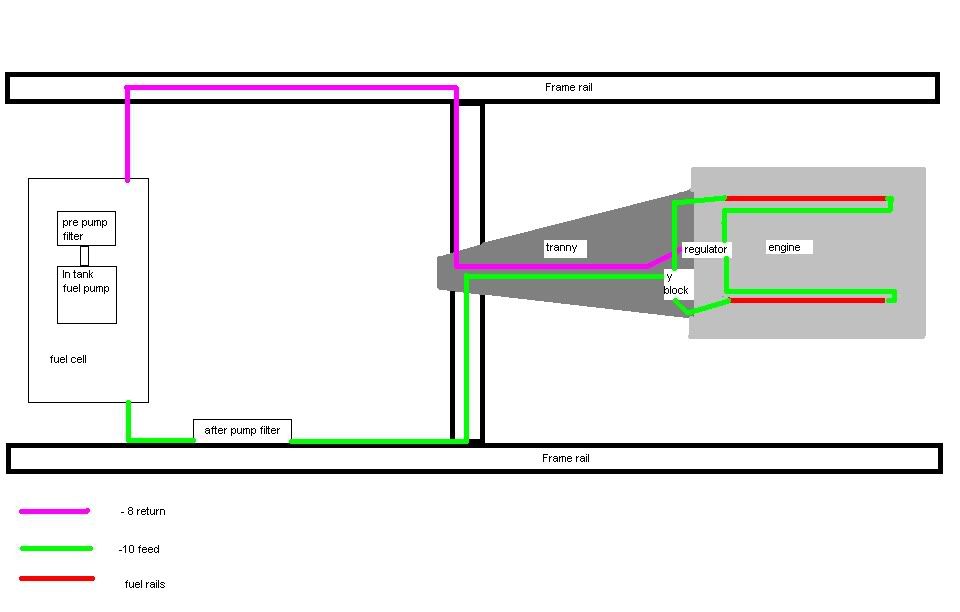

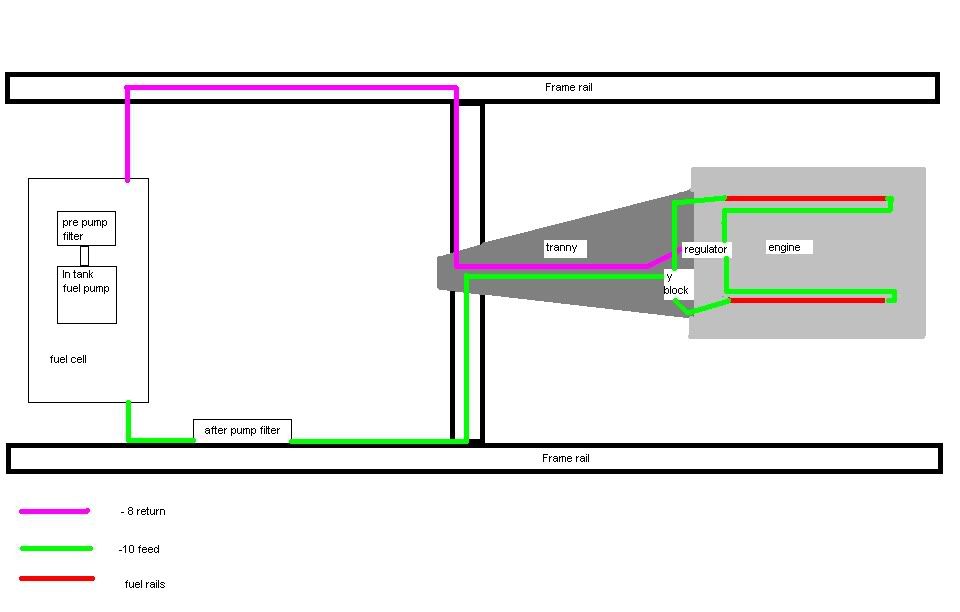

here are my two ideas

Or do you all have any ideas of your own to keep it nice and tidy under the hood?

here are my two ideas

Comment