Originally posted by sinistral

View Post

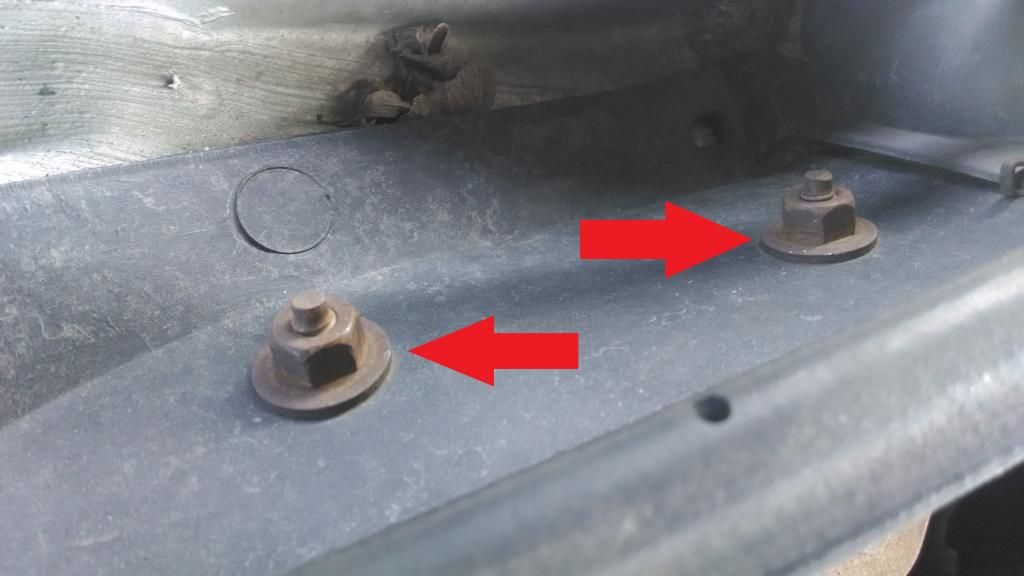

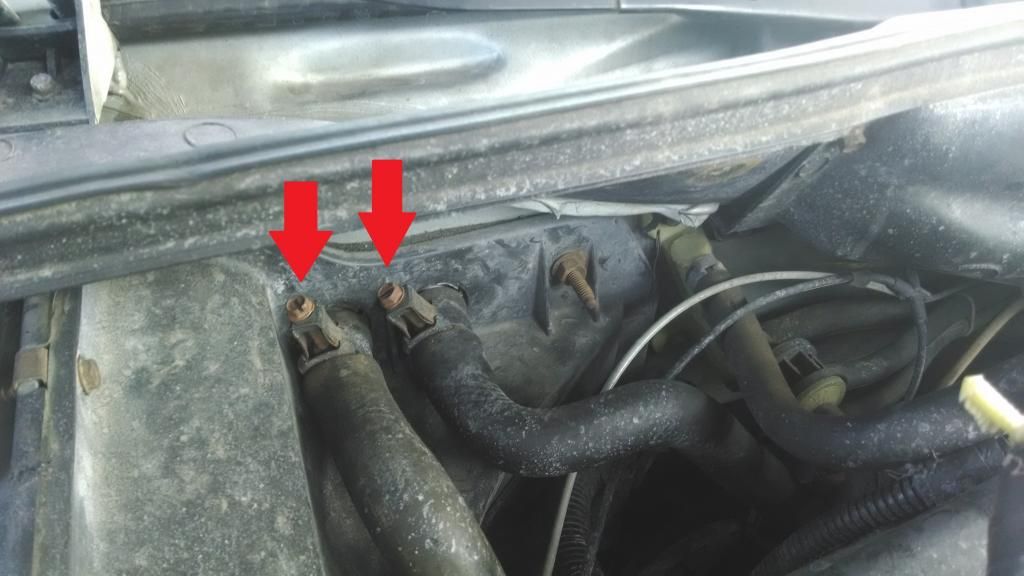

Like I said before, all heater core plenum bolts are supposed to be removed from the inside of the vehicle.

Comment