Thanks Scott. To me "awhile" is a week off from work.  I go back Oct 2nd. I'll be working just about everyday getting the Fairlane to run by next weekend. I've only had 4 days off to work on it since Aug 7th, so I have to get that done. I'll make it out to the shop one day for sure. I'd like to try out your keg setup, and chit chat for awhile.

I go back Oct 2nd. I'll be working just about everyday getting the Fairlane to run by next weekend. I've only had 4 days off to work on it since Aug 7th, so I have to get that done. I'll make it out to the shop one day for sure. I'd like to try out your keg setup, and chit chat for awhile.

I go back Oct 2nd. I'll be working just about everyday getting the Fairlane to run by next weekend. I've only had 4 days off to work on it since Aug 7th, so I have to get that done. I'll make it out to the shop one day for sure. I'd like to try out your keg setup, and chit chat for awhile.

I go back Oct 2nd. I'll be working just about everyday getting the Fairlane to run by next weekend. I've only had 4 days off to work on it since Aug 7th, so I have to get that done. I'll make it out to the shop one day for sure. I'd like to try out your keg setup, and chit chat for awhile.

Dad's driving, so I can enjoy.........

Dad's driving, so I can enjoy.........

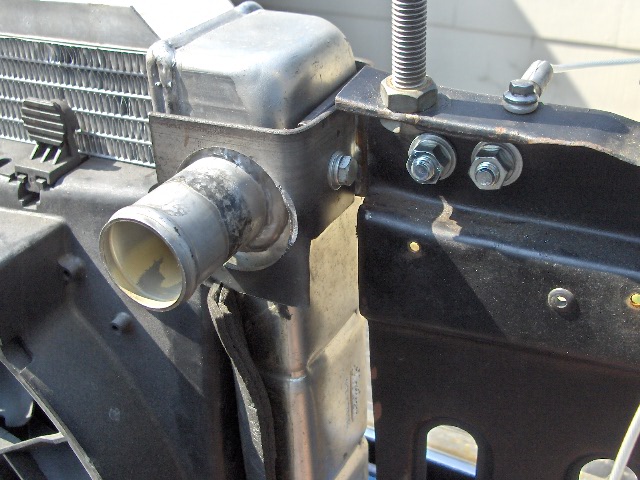

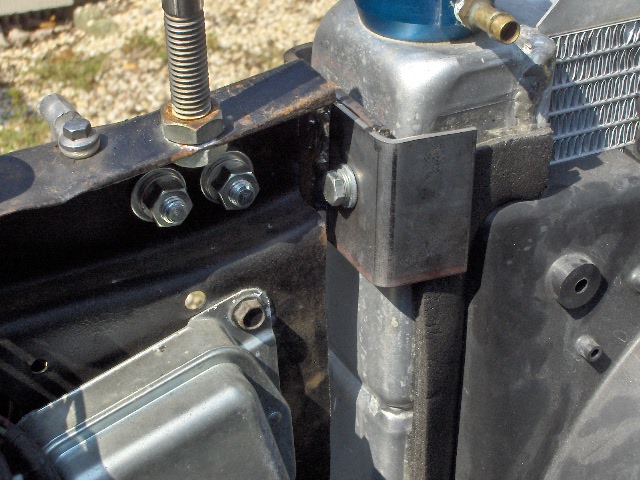

I had just enough room to drill the two bolt holes for the Wilwood pedal.

I had just enough room to drill the two bolt holes for the Wilwood pedal.

Comment