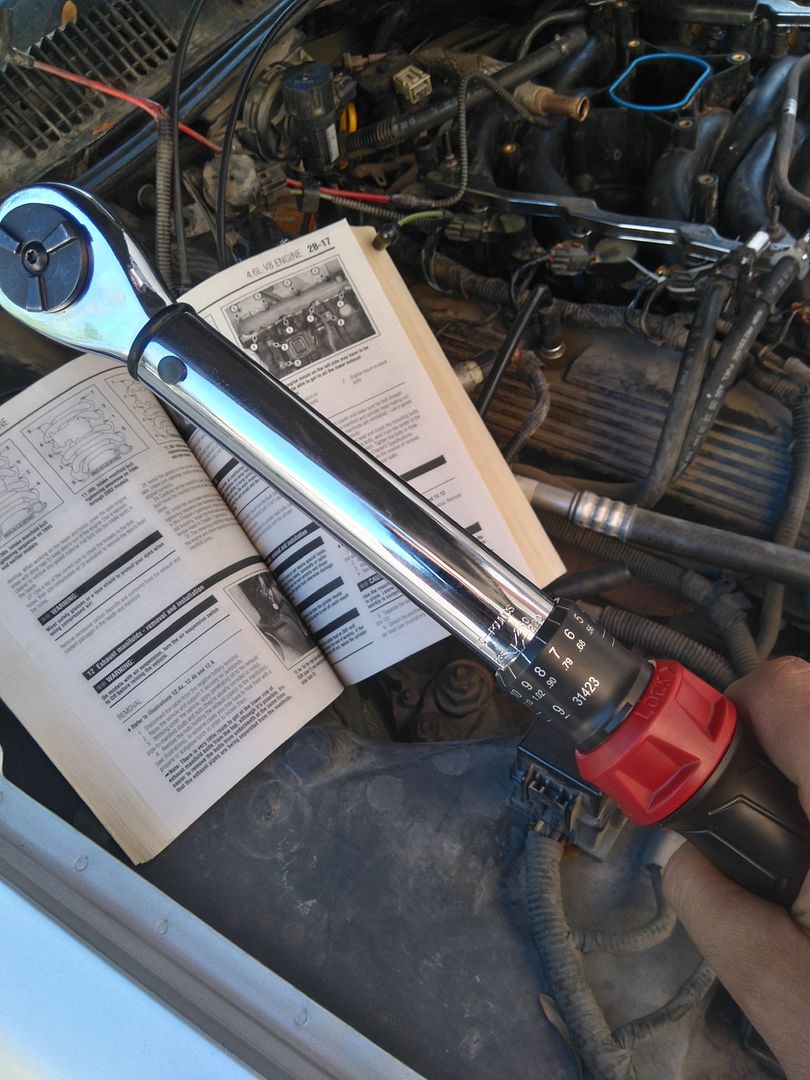

Yes, what you see at the bottom is a cover having a type of fiber or foam board actually remove it to see if the intake manifold was not broken down and is in good condition, I could remove the cover.

The question I had was about the passages of antifreeze in the bottom of the intake manifold where the cooling water passes.

** and I have the epoxy sealant to apply after cleaning all good.

Thank you.

The question I had was about the passages of antifreeze in the bottom of the intake manifold where the cooling water passes.

** and I have the epoxy sealant to apply after cleaning all good.

Thank you.

Comment