I want to rebuild aod myself. Do I need special tools like lip seal protectors or are they optional? Did anybody successfully rebuild theirs?

|

Announcement

Collapse

No announcement yet.

Aod rebuild at home.

Collapse

X

-

Aod rebuild at home.

“Cars are the only thing on earth that will beat you, break you, make you bleed, make you cry, spend all your money, spend all your time, not work and not care that you will love more, the more they abuse you.” -AnonymousTags: None

-

Unless you work at a transmission shop, I wouldn't.Pete ::::>>> resident LED addict and CFI defector LED bulb replacements

'LTD HPP' 85 Vic (my rusty baby) '06 Honda Reflex 250cc 'Baileys' 91 Vic (faded cream puff) ClifFord 'ODB' 88 P72 (SOLD) '77 LTDII (RIP)

sigpic

sigpic

85HPP's most noteworthy mods: CFI to SEFI conversion w/HO upperstuff headers & flowmasters P71 airbox Towncar seats LED dash light-show center console w/5 gauge package LED 3rd brake light 3G alternator mini starter washer/coolant bottle upgrade Towncar power trunk pull underhood fuse/relay box 16" HPP wheels - police swaybars w/poly rubbers - budget Alpine driven 10 speaker stereo

-

I have built numerous AOD/AODE/4R70W transmissions at home, including the wide ration AOD in the 89 CV LX. It Can be done, but you do need special tools and I highly recommend an ATSG repair manual.Last edited by 88grandmarq; 01-16-2012, 01:35 PM.2003 Town Car Signature - 3.27 RAR, Dual exhaust and J-mod - SOLD 9/2011

89 Crown Victoria LX HPP -- SOLD 9/2010

88 Grand Marquis LS - The Original -- Totaled 5/2006

I rebuild AOD/AODE/4R70W/4R75E transmissions....Check out my Facebook page: https://www.facebook.com/pages/North...48414635312478

Comment

-

my uncle did one for his fox body back about 10-12 years ago. It was his first and so far only trans rebuild he got a good rebuild manual and some videos he ordered somewhere and borrowed some tools from a local trans shop. He said it wasnt really all that bad just took alot of patience. So far that trans has 62000 miles on it and its still going strong. He also mentioned that he never had to disassemble the valve body. The reason he had to rebuild it was because it lost OD.

Comment

-

I'm thinking I'll go ahead and do this, also-- probably start a thread with photos, instructions (as I best interpret them), and probably quite a LOT of questions!

Found a local clean core for $75. May not need a rebuild, but a large part of my excuse is that I want to see an automatic trans torn down. I'm a hands-on guy and if I want to take and pass the ASE auto trans certification, I'm going to learn a great deal more by actually going through a transmission.

I'm picking up the transmission on Thursday. Paycheck hasn't cleared yet (%$@#), so I'll order whatever instructional video you guys most highly recommend on thursday, also.

Will set up a table next to my toolbox at work; it'll be fine if it's not there indefinitely.

Any suggestions on where to source parts, or is a napa rebuild kit just fine?

And, maybe a list of specialty tools so I can start shopping around? ... I wonder if I could just borrow them from a local trans shop?

Comment

-

lol... I don't think they would go for that.Originally posted by BerniniCaCO3 View Post... I wonder if I could just borrow them from a local trans shop?

I wish those brave enough to try good luck, its going to be quite the experience... hopefully a good one.Pete ::::>>> resident LED addict and CFI defector LED bulb replacements

'LTD HPP' 85 Vic (my rusty baby) '06 Honda Reflex 250cc 'Baileys' 91 Vic (faded cream puff) ClifFord 'ODB' 88 P72 (SOLD) '77 LTDII (RIP)

sigpic

sigpic

85HPP's most noteworthy mods: CFI to SEFI conversion w/HO upperstuff headers & flowmasters P71 airbox Towncar seats LED dash light-show center console w/5 gauge package LED 3rd brake light 3G alternator mini starter washer/coolant bottle upgrade Towncar power trunk pull underhood fuse/relay box 16" HPP wheels - police swaybars w/poly rubbers - budget Alpine driven 10 speaker stereo

Comment

-

Oh! To verify:

A 1990 mustang AOD is exactly the same transmission, case and all, as a 1990 GM AOD?

I know where was something where the lincolns --different body-- also had different length tails on the transmissions, so they wouldn't just bolt in unless you had a different length driveshaft cut.

Comment

-

I believe it is the same except for the HO governor and shift lever....

87 Ford LTD Crown Victoria Country Squire Station Wagon. 4.10's, Repacked Trac Loc, Boxed LCA's, Explorer Intake, 65mm T-body, 'Stang Cam, 'Stang Air tube, K&N, GT-40X Heads, 1" Spacer, 1 5/8 BBK's, 2.5" Pypes X-pipe w/high flow cats, Single Chamber Thunderbolts, B&M 'vertor, Po-lice Swaybars.

91 Mercury Grand Marquis Colony Park Station Wagon. K-Code, 4.10's, Repacked Trac Loc, MK VII LSC Engine, 'Stang Upper Intake, Stang Air Tube, K&N, 65 mm T-Body, 'Stang Headers, 'Stang Cat Pipe,'Stang Torque Convertor, 2 Chamber Thunderbolts.

Comment

-

wittrans.com,bulkpart.com,transmissioncenter.org also try otc for tools. tools arent cheap shop around use ebay or talk to local trans shops to buy tools through them.now if you want to do a wide ratio trans price goes up and remember you have to be super clean when building a trans. after i did my wide ratio aod it cost me $1800 to $2000 from front to back with tools i also splurged on a torque converter,valve body,powder coated case,cooler,braided lines.you can do it a lot cheaper so do alot of research and price shopping to cut cost.

just a small list from badshoeprodutions

#1 thrust washers; .050”-.054” E0AZ-7D014-A

.068”-.072” E0AZ-7D014-B

.085”-.089” E0AZ-7D014-C

.102”-.106” E0AZ-7D014-D

.119”-.123” E0AZ-7D014-E

Rev./low servos; 1 ring E0AZ-7D189-A

2 rings E0AZ-7D189-B

3 rings E0AZ-7D189-C

Direct clutch snap rings (steel drum); .052” F3AZ-7D483-A

.066” F3AZ-7D483-B

.080” F3AZ-7D483-C

.094” F3AZ-7D483-D

All reverse and (cast) forward snap rings; .060” F3LY-7D483-A

.074” F3LY-7D483-B

.088” F3LY-7D483-C

.102” F3LY-7D483-D

Forward clutch (steel drum) snap rings; .062” F0SZ-7D483-A

.076” F0SZ-7D483-B

.090” F0SZ-7D483-C

.104” F0SZ-7D483-D

1-½” overdrive band E0AZ-7F196-A

2” overdrive band F2TZ-7F196-A

Intermediate pressure plate for 3 fibers F2AZ-7B066-A

Intermediate pressure plate for 4 fibers 3L3Z-7B066-B

Select fit intermediate steel plates .071” XL3Z-7B442-AA

.081” XL3Z-7B442-BA

.091” XL3Z-7B442-CA

.101” XL3Z-7B442-DA

Mechanical diode one-way clutch F8AZ-7A089-AA

Rev. drum for above diode clutch 3L3Z-7D044-AA

Stamped steel direct drum upgrade F6AZ-7F283-AA

Snap ring for holding diode to drum 391267-S

Direct clutch piston for steel drum 3L3Z-7A262-AA

One piece 2-3 accumulator upgrade F7AZ-7H292-AB

TV linkage bushing for throttle body E0AZ-7F330-A

Dipstick tube o-ring 391308-S

Cooler line filter kit Motorcraft p.n. FT 168

Comment

-

Hell yeah! Go for it man... i would be interested in seeing your build. Just because you never have built one before dosen't mean you can't... and if it dosen't work out, well you live and learn and hopefully do it right the next time. Probably a matter of taking your time and being very detail oriented.Originally posted by BerniniCaCO3 View PostI'm thinking I'll go ahead and do this, also-- probably start a thread with photos, instructions (as I best interpret them), and probably quite a LOT of questions!

Found a local clean core for $75. May not need a rebuild, but a large part of my excuse is that I want to see an automatic trans torn down. I'm a hands-on guy and if I want to take and pass the ASE auto trans certification, I'm going to learn a great deal more by actually going through a transmission.

I'm picking up the transmission on Thursday. Paycheck hasn't cleared yet (%$@#), so I'll order whatever instructional video you guys most highly recommend on thursday, also.

Will set up a table next to my toolbox at work; it'll be fine if it's not there indefinitely.

Any suggestions on where to source parts, or is a napa rebuild kit just fine?

And, maybe a list of specialty tools so I can start shopping around? ... I wonder if I could just borrow them from a local trans shop?

Have you done a shift kit before at least?

Comment

-

I have not even done a shift kit before; starting this in rather dire ignorance (ignorance that is the main thing I wish to correct for in this project!).

Picking up my core tomorrow night. Ordering the manual tomorrow also.

Found a shop just 2 miles from work, and I think they'll bear with me on this. I appreciate that I won't be their best business; a diy customer who is both short on money, but long on questions! So I'll try not to abuse them, and if their prices are not $100 beyond napa, etc., I'll get my rebuild kit through them and any other parts. If they are able to and the cost is palatable, pay them to test the finished result before installation.

Watched a youtube video of a self-proclaimed redneck disassembling his 1988 aod. It looked like he needed no special tools, at least, through removing the gear sets. He had not yet taken apart any clutch packs however at the point that I stopped watching-- maybe that's where it gets more devilish. I noted, that he noted, exactly where the springs and (pistons?) came out of the valve body, and he was definitely using a manual himself.

I know, and have been bitten by not following, the KISS principle.

Yet, I am tempted, to make this build even more worthwhile, to convert to wide ratio gears?

I was reading up at becontrols.com, and what I understand is that the gear sets simply have different ratios internally (between sun, planet, and ring), but that they drop right in to the aod casing, no mods needed?

Would I then buy a 4r70w core too, for the gear sets, and a rebuild kit for a 4r70w?

Any other worthwhile modifications? Beyond the wide ratio --for more torque, which will be better for my HO engine anyway-- anything for durability?

I do still need to keep the price down, in case it doesn't work, really; and I don't need serious performance. An HO engine is still just 220hp iirc.

a final question out of curiosity.

What usually warrants a transmission rebuild?

I'm envisioning that clutch packs are like brake pads: designed to wear a certain amount normally, as in the instant of engagement and disengagement there will be slippage, they eventually wear through and need to be replaced?

Does this mean you can get to "metal on metal" when the clutch friction material is completely gone?

Or do most transmissions need rebuilds, to clean clutch material out of the valve body, which could have caused sticking valves?

...I still need to see one apart to see where the band comes in, if the band is in fact a physical, steel band, that can fail. When someone says, "my overdrive band failed," are they simply referring to the clutches that operate that gear set?

Comment

-

Alright!

Doing a build log, right here.

I bought an AOD core for $75 from a fellow off craigslist, 15miles away. He said it "ran fine," and the fluid was clean. I'll find out!

Finally this Friday I tore it down, taking it apart at a Mr. Bill Norris' shop up the street from my work.

Here is the transmission with the torque converter out. What took me a bit to grasp, was a unique aspect of the AOD. Well, almost unique-- apparently VW and "ATX" (never heard of them), had a transmission like this too.

For 3rd gear, that smallest shaft there goes all the way through and directly drives the driveshaft, no planetaries involved. The middle shaft does 1st, 2nd, and OD, and the outermost shaft is fixed, never spins, and holds the stator rigid while the two impellers spin around it. The stator redirects fluid flow in the torque converter. The middle shaft goes to the front of the torque converter, the driven portion, while the back is the driving portion and is fused to the shell, which wraps around the whole package of the converter and is bolted to teh engine flywheel. Apparently, the center shaft, the direct drive shaft, does not make use of the torque converter fluid coupling at all, but instead has a smaller damper (like the transmission accumulators maybe?) to take the shock while the trans and engine match speeds. This is I am told a major contributor to OD shudder, and joining the center damper to the turbine in the converter is supposed to help this.

The tailshaft is off in the background, and the governor (and it's retaining ball!) sitting in the red bin. There is some putty, for want of a more technical term, that was in the detent where the ball was sitting. This is apparently used to secure the ball during reassembly, so it was a sure sign someone had already been in the trans.

The bottom cover came off next, the filter comes right out, and then the valve body. IIRC, there are some bolts that are not the same length as others. The easy, lazy way to do this, is just back them out but never wholly remove any bolt, leaving them right where they go. Set it aside.

I forgot to take a photo of the accumulators!

They're held in with snap rings. Take a screwdriver and grind it out like this; perfect snap ring removal tool. Also immensely useful were these: http://www.amazon.com/Channellock-74...ies/B00065TGQI

Slide hammers to pull the pump out:

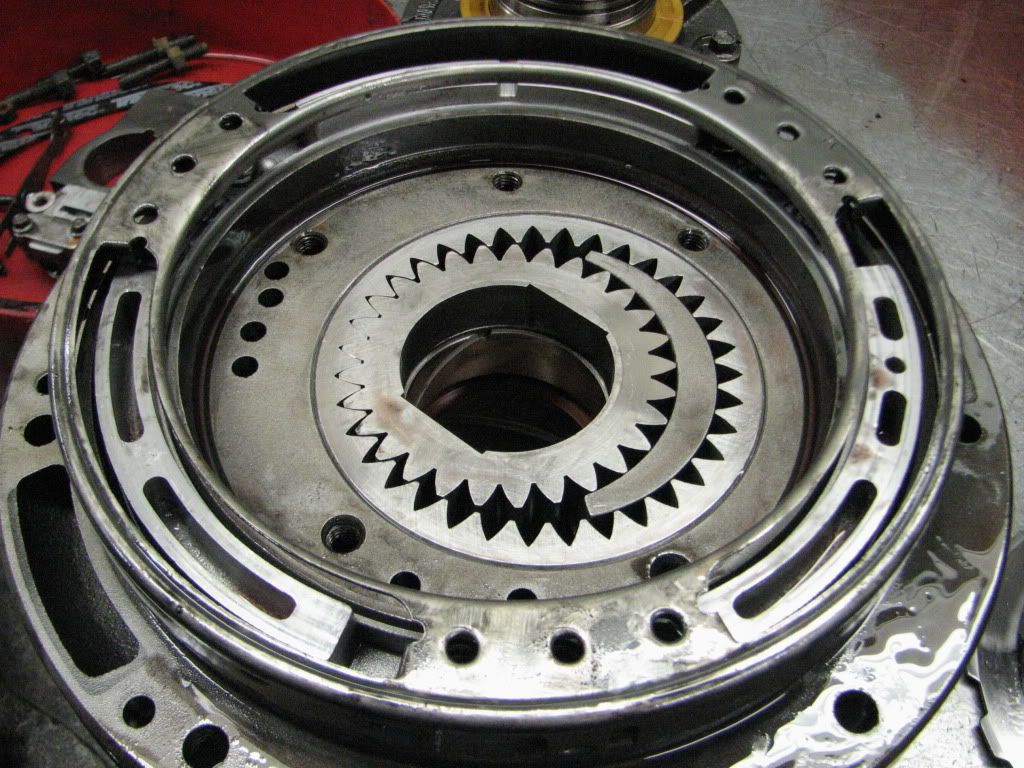

Unbolted the top plate of the pump to take a look-see. Note that there are still machine marks on the surface of the pieces, no burnished marks indicating undue wear. If you remove a piece, mind to put it back with the same orientation (you could put it upside down), to keep the wear pattern even: just like putting pistons back in their respective cylinders when rebuilding an engine. Also wanted to watch the other face (removed, not shown) that rubbed against the gears, to check for any worn tracks. It was flat and smooth and still had machine marks also. I understand that these pumps are bullet proof: barring any metal bits from somewhere else in the tranny that might lock one up, of course!

Pulling out the direct drive shaft:

Here's the first gear set. Note a few hot spots, the little spots of discoloration, but nothing serious. This face is NOT the wear face, so the previous rebuilder must have flipped it around-- a smart move.

Here's a thrust bearing. Used a pick to pop off the cap. I forgot what my mentor, Mr. Bill Norris, was saying to look for; although I suppose a cracked roller would go without saying. Mostly you don't need to pry the top off: just rotate with light pressure from your fingers, and if it feels uneven, grabs somewhere, etc., there's an issue. On his other bench he had a 4L60E that had a cracked planetary: what he found was that the thrust bearing had bound and come apart, circulated through the planetary gears, and cracked the housing that retained them. Lady driving that (suburban?) probably did not have much warning, no obvious noise and time to catch it when it was just a binding bearing, before the bearing killed the planetaries, which jumped the repair bill by $100-$300 depending on where he sources the gears (taiwan, GM) after his markup.

Aha! here's why someone else rebuilt this. The direct drive drum is badly gouged, something metal this way went. It's warped, just a bit, which is surmised from the fact that the backing plate for the clutches took some encouragement to finally get out. It was bound up a bit. These clutches are also noticeably darker than any of the other clutch sets, which were in fact, fine. Again... missed some things. The reverse band, rarely included in a rebuild kit, was a beefy piece of work and showed no wear, the OD band was still OK on this one but showed normal crackling of the friction material. Not darkened. These direct drive clutches were the worst. The previous rebuilder was cheap and reinstalled this direct drive drum after cleaning out the trans, but I will not be. I'm getting a new (or non-scoured salvage) drum for my build.

Last edited by BerniniCaCO3; 01-29-2012, 10:11 PM.

Last edited by BerniniCaCO3; 01-29-2012, 10:11 PM.

Comment

-

Pictures didn't post correctly, please fix!Last edited by Brown_Muscle; 01-29-2012, 09:51 PM.-Phil

sigpic

+1982 Ford LTD-S Police Car. Built 351w, Trickflow 11R 190 Heads, Holley Sniper EFI, RPM Intake+ Hyperspark dizzy, WR-AOD, Full exhaust headers to tails. 3.27 Trac-Lok Rear. Aluminum Police Driveshaft. Speedway Springs+Bilstein Shocks, Intermediate Brakes, HPP Steering Box.

+2003 Acura CL Type S 6-speed

Comment

-

step ahead of you!

Switched from picasa to photobucket.

Next step is the rebuild: lip seals and clutches, and reassembly. I understand more special tools will become involved, for the lip seals, and I'll document those.

So far it hasn't been bad: just slide hammers, a pick, a ground screwdriver, some electrical nippers.

I'm actually going to take apart a SECOND transmission, an aode, to get the 2" overdrive band and other ancillary hard parts that need to go with it.

Bought that late last night, it's still in my car.

Ordering a better rebuild kit, slightly modded f52tt torque converter, A++ servo, and something about a mechanical diode and spot welded retaining ring for the sprag roller? These were among the most highly recommended improvements, and for me, what I want to do is modify this trans just to be a bit stronger, beefier, more durable for a long life. I've got the HO swap but that's it; not joining the ranks of 400hp performance grand marquis', so no shift kit or messing with the valve body this time around.

So far all I did was rip all the guts out, but I'm not clear on many things. Gonna find out next week!Last edited by BerniniCaCO3; 01-29-2012, 10:25 PM.

Comment

Comment